Expanded Metal Manufacturing Process

Expanded Metal Manufacturing Process

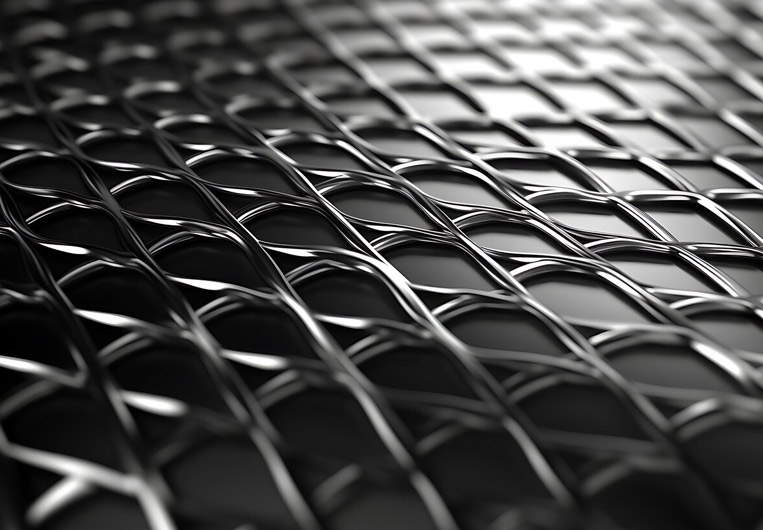

Expanded metal stands out as a durable, lightweight and environmentally friendly material used in different sectors. The production process consists of a series of stages such as cutting, expanding and shaping sheet metal. This process ensures that a product that is both aesthetic and functional is obtained.

1. Material Selection and Preparation

The first step in expanded metal production is to select the sheet metal to be used. Metals such as steel, stainless steel, aluminum or copper are generally preferred. The thickness and structural properties of the material determine the durability and usage area of the final product.

2. Cutting and Expansion Process

Sheet metals are cut with special machines and expanded by pulling. This process creates regular and aesthetic openings on the metal.

- Cutting: Patterns such as diamond, hexagon or square are opened on the sheet metal.

- Expansion: A larger surface area is obtained by pulling the cut metal. This allows the material to have a light but durable structure.

3. Shaping and Customization

After the cutting and expanding process, the metal is arranged according to the desired size and shape. Different patterns and measurements are applied during the production process and special solutions are offered for the project.

- Coating Processes: The material is galvanized or powder coated to provide protection against rust or to provide an aesthetic appearance.

4. Quality Control and Finishing Processes

In the final stage, the product goes through quality control processes. The smoothness of the cut openings, the durability of the material and its dimensions are carefully examined. This stage ensures that the expanded metal can be used in projects without any problems.

The expanded metal production process is carried out in an efficient and environmentally friendly way with the help of modern technologies. This material, which serves many sectors with its durable and lightweight structure, combines functionality with aesthetics. The care in the production process ensures that the expanded metal is both long-lasting and high-performance.